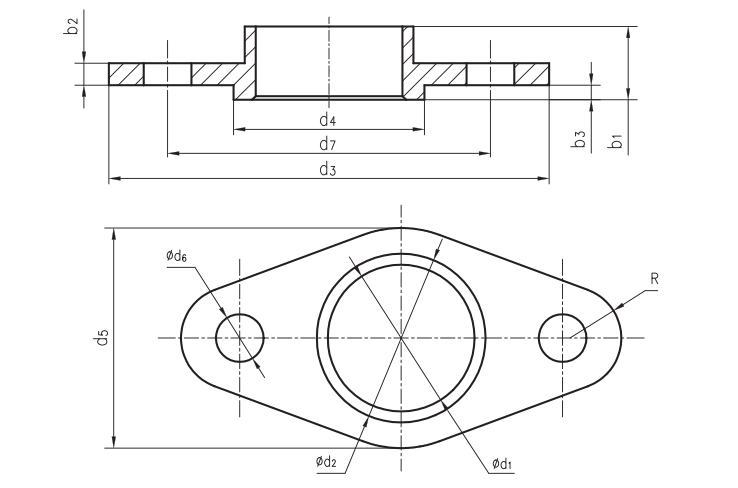

| 订购代码 | d1 mm | 公差 mm |

d2 mm | d3 mm | d4 mm | d5 [mm] | d6 [mm] | d7±0.2 [mm] | b1 [mm] | b2 [mm] | b3 [mm] | R [mm] |

| GFL-10 | 10 | +0.025/+0.083 | 12 | 30 | 14 | 15 | 4.5 | 22 | 6 | 2 | 1 | 4 |

| GFL-12 | 12 | +0.025/+0.083 | 14 | 36 | 16 | 18 | 4.5 | 26 | 6 | 2 | 1 | 4.5 |

| GFL-14 | 14 | +0.025/+0.083 | 16 | 42 | 18 | 21 | 5.5 | 30 | 6 | 2 | 1 | 5 |

| GFL-16 | 16 | +0.025/+0.083 | 18 | 48 | 20 | 24 | 5.5 | 34 | 6 | 2 | 1 | 5.5 |

| GFL-18 | 18 | +0.025/+0.083 | 20 | 54 | 22 | 27 | 6.5 | 39 | 6 | 2 | 1 | 7 |

| GFL-20 | 20 | +0.040/+0.124 | 23 | 60 | 26 | 30 | 6.5 | 44 | 10 | 3 | 2 | 7 |

| GFL-25 | 25 | +0.040/+0.124 | 28 | 75 | 30 | 35 | 6.5 | 55 | 10 | 3 | 2 | 8.5 |

| GFL-30 | 30 | +0.040/+0.124 | 34 | 90 | 36 | 40 | 8.5 | 66 | 10 | 3 | 2 | 10 |

| JFL-10 | 10 | +0.025/+0.083 | 12 | 30 | 14 | 15 | 4.5 | 22 | 6 | 2 | 1 | 4 |

| JFL-12 | 12 | +0.025/+0.083 | 14 | 36 | 16 | 18 | 4.5 | 26 | 6 | 2 | 1 | 4.5 |

| JFL-14 | 14 | +0.025/+0.083 | 16 | 42 | 18 | 21 | 5.5 | 30 | 6 | 2 | 1 | 5 |

| JFL-16 | 16 | +0.025/+0.083 | 18 | 48 | 20 | 24 | 5.5 | 34 | 6 | 2 | 1 | 5.5 |

| JFL-18 | 18 | +0.025/+0.083 | 20 | 54 | 22 | 27 | 6.5 | 39 | 6 | 2 | 1 | 7 |

| JFL-20 | 20 | +0.040/+0.124 | 23 | 60 | 26 | 30 | 6.5 | 44 | 10 | 3 | 2 | 7 |

| JFL-25 | 25 | +0.040/+0.124 | 28 | 75 | 30 | 35 | 6.5 | 55 | 10 | 3 | 2 | 8.5 |

| JFL-30 | 30 | +0.040/+0.124 | 34 | 90 | 36 | 40 | 6.5 | 66 | 10 | 3 | 2 | 10 |

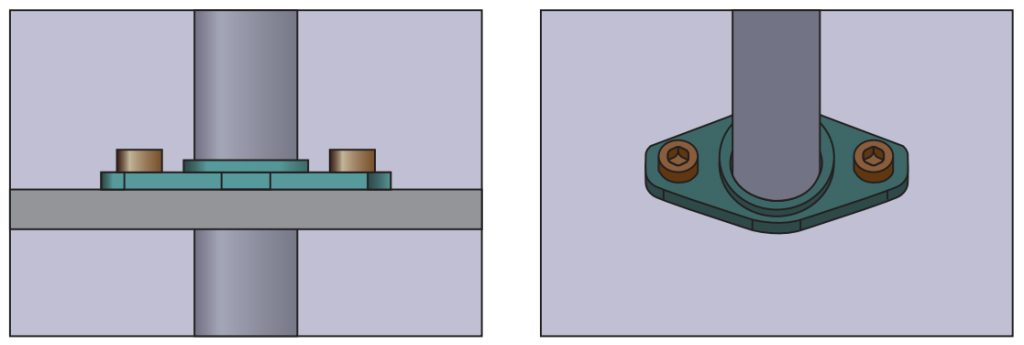

根据要求的不同,可以采取不同的安装方式。当只有较小的径向载荷时,仅用 2 个螺栓将法兰轴承安装在平面上即可。当有较大径向载荷时,建议用垂直于载荷方向的加强面上的一个孔来支撑法兰轴承。这个孔允许有较大的公差,因为它只是对法兰轴承起辅助支撑作用。为了使轴承可以承受更高的径向载荷,可以将法兰轴承压入推荐的公差为 H7 的基座孔中。辅助的螺栓可以确保轴承和基座的配合。安装免维护法兰轴承时,不需要特殊的材料或工具。